- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

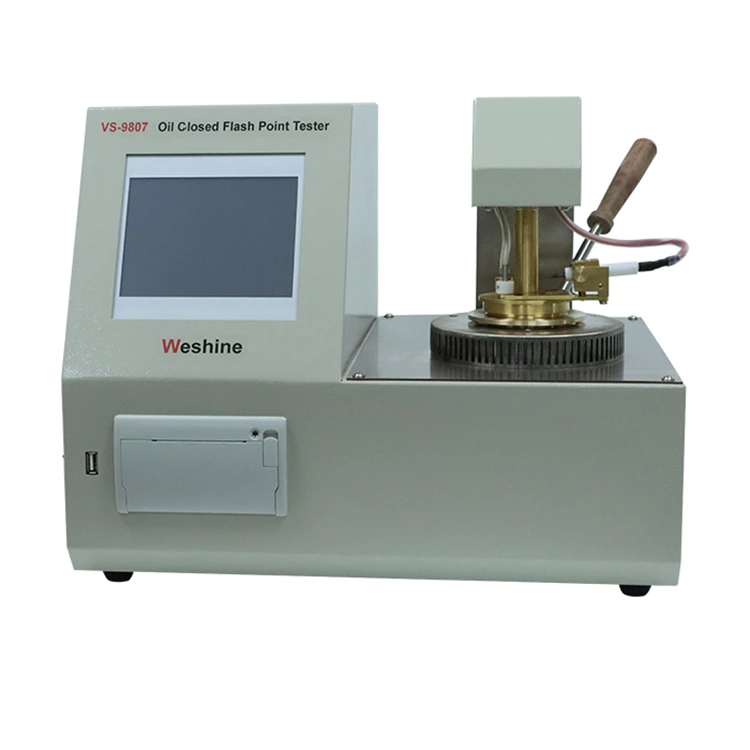

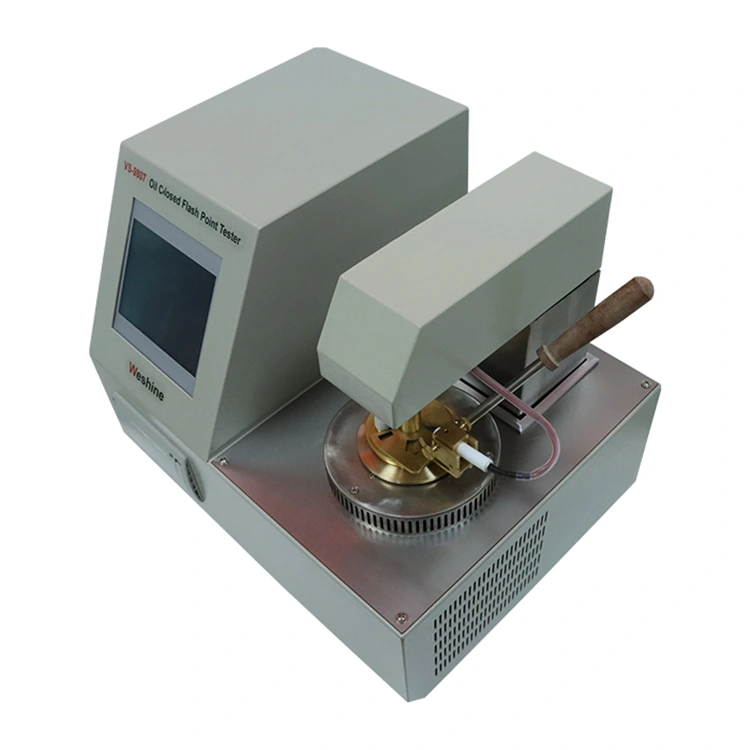

VS-9807 Flash Point Tester

In the competitive and highly regulated landscape of petroleum testing, finding a flash point tester that balances versatility, accuracy, and compliance is a top priority for industry professionals. For oil refineries, railway fuel facilities, aviation fuel suppliers, and research institutions, the VS-9807 Fully Automatic Closed (Open) Flash Point Tester stands out as a transformative solution. Unlike specialized tools like the cleveland open cup flash point tester (which focuses solely on open cup testing), the VS-9807 integrates both closed and open cup capabilities—making it a all-in-one instrument that meets strict standards such as GB/T261-2008 and ISO2719. This flexibility, paired with unmatched performance, delivers tangible value to every stage of petroleum product analysis, making it a must-have for teams striving for excellence in both closed and open cup flash point testing.

Model:VS-9807

Send Inquiry

VS-9807 Flash Point Tester: 5 Key Advantages for Petroleum Industry Excellence

In the competitive and highly regulated landscape of petroleum testing, finding a flash point tester that balances versatility, accuracy, and compliance is a top priority for industry professionals. For oil refineries, railway fuel facilities, aviation fuel suppliers, and research institutions, the VS-9807 Fully Automatic Closed (Open) Flash Point Tester stands out as a transformative solution. Unlike specialized tools like the cleveland open cup flash point tester (which focuses solely on open cup testing), the VS-9807 integrates both closed and open cup capabilities—making it a all-in-one instrument that meets strict standards such as GB/T261-2008 and ISO2719. This flexibility, paired with unmatched performance, delivers tangible value to every stage of petroleum product analysis, making it a must-have for teams striving for excellence in both closed and open cup flash point testing.

1. Unmatched Automation: Streamline Every Flash Point Testing Workflow

Automation is the cornerstone of the VS-9807’s efficiency—and a key upgrade from both traditional manual testers and even semi-automatic models like some cleveland open cup flash point tester variants. Traditional flash point tester setups force teams to manually handle lid operation (for closed cup), ignition, cooling, and report generation—introducing human error and slowing down workflows, especially when switching between closed and open cup modes. The VS-9807 eliminates these pain points by automating the entire process end-to-end: from inputting test parameters (whether for closed cup diesel testing or open cup lubricant analysis) to printing final results, no manual intervention is needed. This not only cuts testing cycles by up to 30% but also ensures consistent results across every sample—critical for petroleum facilities processing dozens of batches daily. For busy labs that once had to juggle a separate cleveland open cup flash point tester for specific tasks, this all-in-one automation frees up technical staff to focus on high-value work like data analysis or quality control strategy, turning a basic testing tool into a productivity driver.

2. Precision Engineering: Accuracy That Outperforms Standard Flash Point Testers

In petroleum analysis, even a small error in flash point readings can lead to non-compliant products, safety risks, or regulatory penalties—especially for high-viscosity or high-flash-point products often tested with a cleveland open cup flash point tester. The VS-9807, as a premium flash point tester, delivers precision that meets and exceeds industry expectations for both closed and open cup scenarios: it achieves a repeatability of ≤2°C (ensuring the same result across multiple tests of the same fuel, whether gasoline in closed cup or heavy oil in open cup) and a reproducibility of ≤4°C (guaranteeing consistency between different operators or labs). With a temperature resolution of 0.1°C and 0.6% precision, it captures even the smallest temperature variations—essential for detecting subtle flash point shifts in aging lubricants or refined fuels. Adding to its reliability is the platinum heating wire ignition system: unlike the inconsistent flame ignition used in some older cleveland open cup flash point tester models, this method ensures every test (closed or open) starts under identical conditions, eliminating variability that can skew results. For petroleum teams, this precision means confident compliance—whether they’re testing to GB/T261-2008 for closed cup or adapting to open cup requirements similar to the Cleveland method.

3. Adaptive Intelligence: Smart Control for Any Petroleum Testing Scenario

The VS-9807 isn’t just a flash point tester—it’s a “smart” tool designed to adapt to real-world challenges, including those unique to open cup testing (a key use case for the cleveland open cup flash point tester). Its adaptive PID control algorithm automatically adjusts heating rates to match industry-standard curves, whether for closed cup diesel (where precise temperature ramping prevents premature vaporization) or open cup heavy oils (where slower heating aligns with cleveland open cup flash point tester best practices). A major pain point for petroleum facilities in diverse locations (e.g., high-altitude refineries vs. coastal storage depots) is atmospheric pressure: this variable can drastically skew open cup results (a common issue with standalone cleveland open cup flash point tester models) if unaccounted for. The VS-9807 solves this with atmospheric pressure auto-correction, calculating real-time adjustments to maintain accuracy—whether testing in a mountain lab or a coastal facility. This intelligence means teams get reliable results no matter the test mode or environment, turning a potential obstacle (like switching between closed and open cup) into a seamless process.

4. User-Centric Design: Power Meets Simplicity for All Flash Point Testing Needs

Advanced technology shouldn’t mean complexity—and the VS-9807’s design ensures it’s accessible even for teams new to balancing closed cup and open cup workflows (a common challenge when adding a cleveland open cup flash point tester to a lab). As a user-friendly flash point tester, it features an LCD TFT true-color touch screen paired with a fully Chinese man-machine interface, making it easy to switch between closed and open cup modes with just a few taps. Clear prompt menus guide users through parameter entry: whether setting pre-value temperatures for closed cup gasoline testing or adjusting ignition intervals for open cup lubricant analysis (mimicking the precision of a cleveland open cup flash point tester), the system eliminates guesswork. Another standout feature is the thermal-sensitive micro-printer with offline capability: it generates fast, clear reports for both test modes—critical for facilities where internet or power stability is a concern, and a big upgrade from some cleveland open cup flash point tester models that require separate software for reporting. Unlike bulky setups that force labs to dedicate space to both a closed cup tester and a cleveland open cup flash point tester, the VS-9807’s compact design saves space while delivering dual functionality. For petroleum labs with rotating staff or tight deadlines, this accessibility is a game-changer.

5. Robust Compliance & Safety: Built for Petroleum Industry Standards (Closed & Open Cup)

Compliance and safety are non-negotiable in petroleum testing—and the VS-9807 embeds both into its design, whether for closed cup testing (per GB/T261-2008) or open cup testing (aligning with requirements often met by a cleveland open cup flash point tester). It strictly adheres to GB/T261-2008 and ISO2719, ensuring test results are recognized by global regulatory bodies, customers, and industry partners—eliminating the risk of rejected batches or costly certification delays, even when switching between test modes. Safety features are tailored to both closed and open cup scenarios: over-temperature protection automatically shuts down the instrument and triggers alarms if temperatures exceed safe limits (critical when testing flammable petroleum products in open cup mode, where fire risks are higher than closed cup). Its stable digital signal processing, powered by a high-speed processor, ensures reliable operation even in demanding industrial environments—from dusty refineries testing diesel (closed cup) to research labs analyzing heavy lubricants (open cup, a task once reserved for a cleveland open cup flash point tester). For petroleum businesses prioritizing regulatory compliance and workplace safety, the VS-9807 isn’t just a versatile flash point tester—it’s a comprehensive safeguard.

Final Verdict: The VS-9807—A Competitive Advantage for Petroleum Excellence

The VS-9807 Fully Automatic Closed (Open) Flash Point Tester isn’t just another flash point tester; it’s a strategic asset that outperforms single-function tools like the cleveland open cup flash point tester by integrating versatility, automation, and precision. Its unmatched automation boosts efficiency, precision engineering guarantees accuracy across closed and open cup modes, adaptive intelligence handles real-world testing challenges, user-centric design ensures accessibility, and robust compliance/safety features mitigate risks. For oil refineries, aviation fuel suppliers, railway facilities, or research institutions, this instrument delivers more than test results—it delivers confidence, productivity, and a edge in a competitive market. If your team demands excellence in both closed and open cup flash point testing, the VS-9807 is the clear choice.