- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

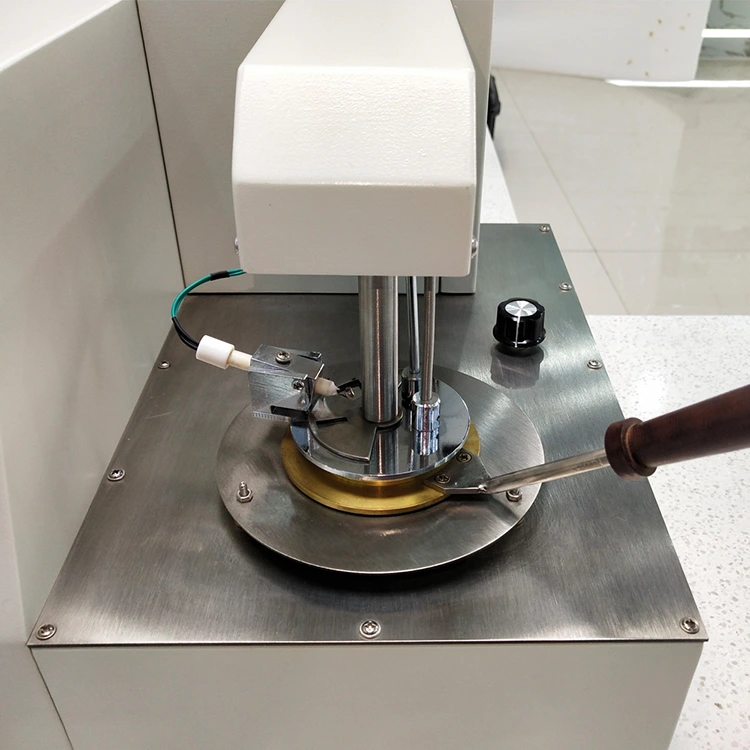

VS-9806 Automatic Closed (Open) Flash Point Tester:

In industries like railway, aviation, electric power, petroleum, and scientific research, accurate flash point testing of petroleum products is non-negotiable for ensuring operational safety and strict quality control. If you’re searching for a reliable flash point tester that balances precision, versatility, and compliance, the VS-9806 Automatic Closed (Open) Flash Point Tester stands out as a cutting-edge industrial-grade instrument. It not only functions as a high-performance closed cup flash point tester but also supports open cup testing—fully meeting national standards GB/T261-2008 and GB/T261-83 to address the rigorous testing demands of modern industries.

Model:VS-9806

Send Inquiry

VS-9806 Automatic Closed (Open) Flash Point Tester: The Best Solution for Petroleum Product Flash Point Testing

In industries like railway, aviation, electric power, petroleum, and scientific research, accurate flash point testing of petroleum products is non-negotiable for ensuring operational safety and strict quality control. If you’re searching for a reliable flash point tester that balances precision, versatility, and compliance, the VS-9806 Automatic Closed (Open) Flash Point Tester stands out as a cutting-edge industrial-grade instrument. It not only functions as a high-performance closed cup flash point tester but also supports open cup testing—fully meeting national standards GB/T261-2008 and GB/T261-83 to address the rigorous testing demands of modern industries.

Why Choose the VS-9806 Flash Point Apparatus?

For petroleum refineries, research labs, or power plants, a subpar flash point apparatus can lead to inaccurate results, risking product defects or safety hazards. The VS-9806 solves these pain points by integrating advanced technology and user-centric design, making it a top choice for:

Routine quality inspections of gasoline, diesel, lubricating oil, and other petroleum products.

Precision flash point experiments in scientific research institutions.

Compliance testing to meet industry regulations (e.g., railway fuel safety standards, aviation fuel quality checks).

Product Overview: A Versatile Flash Point Tester for Every Scenario

The VS-9806 is engineered as a professional flash point apparatus to deliver exceptional accuracy in both closed and open cup flash point determination. Its design prioritizes ease of use and adaptability, with key features that streamline testing workflows:

Intuitive Operation: Equipped with a liquid crystal TFT color touch screen and a fully Chinese human-machine interface. Even new users can quickly set critical parameters—such as preset temperature, test standard (GB/T261-2008/83), atmospheric pressure, and test date—via menu prompts and guided input.

Flexible Software: Open and modular control integrated software allows customization for different testing scenarios. Whether you’re conducting batch tests in a refinery or single precision experiments in a lab, the software adapts to your needs.

Space-Saving Design: With dimensions of 410mm×360mm×270mm, this compact flash point tester fits easily in most laboratory workspaces without sacrificing performance.

Core Functional Features: Reliability Meets Intelligence

As a versatile flash point tester, the VS-9806 combines smart technology with robust functionality to eliminate errors and boost efficiency:

Software Error Correction: Built-in error correction ensures test results are accurate, even in complex environments.

Automatic Atmospheric Pressure Compensation: The instrument automatically adjusts for atmospheric pressure changes and calculates correction values, eliminating external environmental interference—a critical feature for consistent results across different locations (e.g., high-altitude power plants vs. low-altitude refineries).

Micro-Division Detection with Self-Correction: The system performs real-time deviation self-correction, enhancing the reliability of test data for sensitive applications (e.g., aviation fuel testing).

Full Automation: From lid opening and electronic ignition to result detection and data printing—all steps are completed automatically. This reduces manual intervention, cuts down testing time, and minimizes human error.

Automatic Test Vessel Lifting: The test vessel rises and falls automatically, ensuring standardized operations that align with GB/T261 standards—no more inconsistent manual handling.

Safe Electronic Ignition: Unlike traditional flame ignition, electronic ignition is safer and more reliable, making it ideal for use as a closed cup flash point tester (where controlled ignition is critical) and open cup testing modes.

Technical Parameters: Precision You Can Trust

The VS-9806’s technical specs meet or exceed industry standards, confirming its status as a high-precision flash point apparatus. Its temperature control range spans from room temperature to 200°C, which covers the flash point testing needs of most petroleum products—for example, diesel (52-96°C) and gasoline (-45-10°C). In terms of repeatability, it achieves ≤2°C, ensuring consistent results for batch testing like daily refinery quality checks. The reproducibility of ≤±4°C meets strict accuracy requirements for industrial and research applications, such as aviation fuel compliance testing.

With a resolution of 0.1°C, the instrument enables precise temperature measurement, a critical capability for detecting small flash point variations in high-quality lubricants. Its accuracy of 0.5% guarantees reliable data for regulatory reporting, while the heating rate complies with GB/T261-83 and GB/T261-2008 standards to avoid compliance issues. The electronic ignition method is not only safe and efficient but also low-maintenance compared to traditional flame ignition.

The VS-9806 operates normally in environments with temperatures between 10-40°C and relative humidity ≤85%RH, meaning it works reliably in most laboratory and industrial settings without the need for specialized climate control. Its power supply requirement is AC220V 50Hz±5% with a power consumption of <300W, making it compatible with standard laboratory power configurations and eliminating the need for extra wiring.

Who Benefits Most from the VS-9806?

This flash point tester is tailored to the needs of:

Petroleum Industry: Refineries and fuel distributors use it for quality control to ensure products meet safety standards (e.g., preventing low-flash-point gasoline from reaching the market).

Scientific Research Institutions: Labs rely on its precision for experiments on new petroleum-based materials or fuel additives.

Railway & Aviation Sectors: Maintenance teams use it to test fuel quality, ensuring trains and planes operate safely.

Electric Power Plants: It tests lubricating oils and fuel for generators, preventing equipment failures due to substandard fluids.

Final Verdict: The Indispensable Flash Point Apparatus for Quality & Safety

The VS-9806 Automatic Closed (Open) Flash Point Tester isn’t just a flash point tester—it’s a solution for ensuring product quality, regulatory compliance, and operational safety. Its ability to act as both a closed cup flash point tester and open cup tool, combined with advanced features like automatic compensation and full automation, makes it an indispensable asset for any industry relying on accurate petroleum product testing.

If you’re ready to upgrade your flash point testing workflow with a reliable, efficient, and compliant instrument, the VS-9806 is the choice for you.