- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

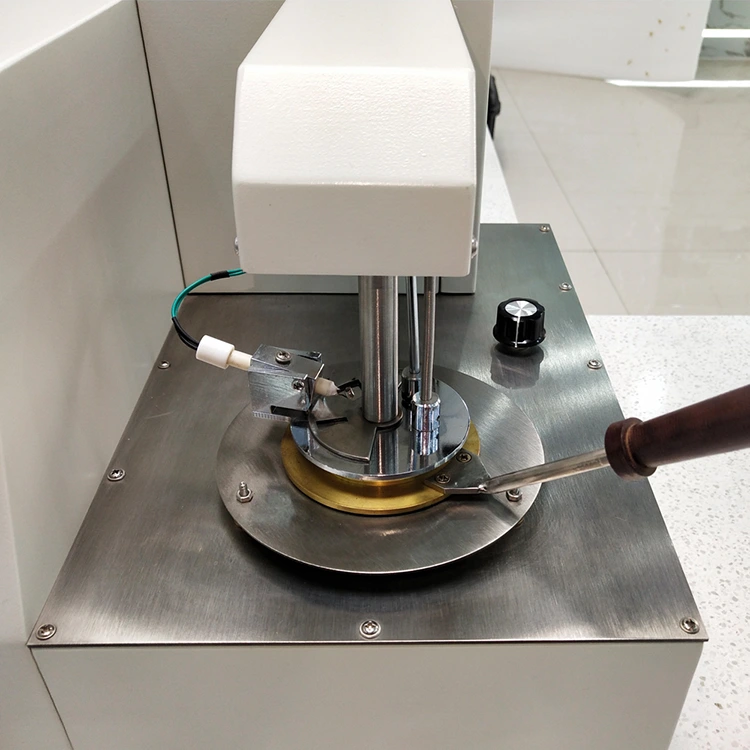

VS-9806 Automatic Flash Point Tester

In the petroleum industry, quality control is the cornerstone of safe operations, regulatory compliance, and trusted product delivery—and accurate flash point testing is a make-or-break step in this process. For refineries, fuel distributors, and petroleum manufacturers, the search for a reliable flash point tester ends with the VS-9806 Automatic Closed (Open) Flash Point Tester. This professional instrument isn’t just a standard flash point apparatus; it’s engineered to precisely measure the closed and open flash points of petroleum products—from gasoline and diesel to industrial lubricants—making it indispensable for safeguarding safety and upholding quality across petroleum, railway, aviation, and electric power sectors that depend on high-performance petroleum-derived fuels.

Model:VS-9806

Send Inquiry

Why VS-9806 Automatic Flash Point Tester is Essential for Petroleum Industry Quality Control

In the petroleum industry, quality control is the cornerstone of safe operations, regulatory compliance, and trusted product delivery—and accurate flash point testing is a make-or-break step in this process. For refineries, fuel distributors, and petroleum manufacturers, the search for a reliable flash point tester ends with the VS-9806 Automatic Closed (Open) Flash Point Tester. This professional instrument isn’t just a standard flash point apparatus; it’s engineered to precisely measure the closed and open flash points of petroleum products—from gasoline and diesel to industrial lubricants—making it indispensable for safeguarding safety and upholding quality across petroleum, railway, aviation, and electric power sectors that depend on high-performance petroleum-derived fuels.

1. Solves Critical Petroleum Quality Control Pain Points

The petroleum industry faces unique quality control challenges: inconsistent flash point test results can lead to non-compliant fuels entering the market, risking equipment breakdowns, fire hazards, or costly regulatory penalties. Unlike basic flash point apparatus that struggle with environmental interference or human error, the VS-9806 is built to eliminate these risks. As a versatile closed cup flash point tester (with open cup testing capability), it delivers consistent, accurate data—even when testing volatile products like gasoline, where small temperature variations can drastically alter flash point readings. For petroleum teams, this means no more second-guessing test results and confident compliance with industry safety standards.

2. Advanced Technology Meets Petroleum Industry Usability

Petroleum quality control teams need tools that balance power with simplicity—especially when managing high-volume testing schedules. The VS-9806 checks both boxes with user-centric design:

It features a liquid crystal TFT color touch screen and a fully Chinese human-machine interface, so operators (even those with limited technical experience) can quickly set critical parameters. This includes adjusting preset temperatures, selecting industry-standard test protocols (such as GB/T261-2008 or GB/T261-83, which are mandatory for petroleum testing in China), inputting atmospheric pressure data, and logging test dates—all guided by clear menu prompts to minimize setup mistakes.

The intuitive design cuts training time and operational delays, a key advantage for petroleum facilities that process dozens of samples daily. Unlike complex flash point tester models that require specialized expertise, the VS-9806 gets teams up and running fast without compromising accuracy.

3. Comprehensive Features for Unmatched Flash Point Testing Accuracy

As a specialized closed cup flash point tester, the VS-9806 includes features tailored to the precision demands of petroleum quality control:

Dual Error Correction: It’s equipped with a software-based error correction function to fix calculation discrepancies, plus a micro-division detection system that performs real-time deviation self-correction. This dual layer of accuracy ensures test results are trustworthy—critical for petroleum products where even a 1°C error could mean the difference between compliant and non-compliant fuel.

Automatic Atmospheric Pressure Compensation: Petroleum facilities operate in diverse locations, from low-altitude refineries to high-altitude storage depots, and atmospheric pressure directly impacts flash point readings. The VS-9806 automatically adjusts for pressure changes and calculates correction values, eliminating environmental variables that plague less advanced flash point apparatus.

Full Automation to Reduce Human Error: Manual steps (like lid opening, ignition, or test vessel handling) are major sources of error in high-volume petroleum testing. The VS-9806 automates every stage: from opening the test chamber lid and initiating electronic ignition to detecting flash points and printing results. Even the test vessel automatically rises and falls to ensure standardized positioning—aligning with GB/T261 standards and removing human inconsistency from the process.

Safe Electronic Ignition: Traditional flame ignition poses fire risks when testing flammable petroleum products. The VS-9806 uses electronic ignition, which is safer, more reliable, and requires less maintenance than flame-based systems—keeping teams protected and the flash point tester running smoothly.

4. Technical Specs That Meet Strict Petroleum Industry Standards

The VS-9806’s technical capabilities are engineered to exceed petroleum quality control requirements:

Temperature Control Range: It operates from room temperature up to 200°C, covering the flash point needs of nearly all petroleum products. This includes low-flash-point fuels like gasoline (typically -45°C to 10°C) and high-flash-point lubricants (often above 150°C), making it a one-stop flash point apparatus for full-range petroleum testing.

Precision You Can Trust: For petroleum quality control, precision is non-negotiable. The VS-9806 delivers a repeatability of ≤2°C (ensuring the same result across multiple tests of the same sample) and a reproducibility of ≤±4°C (guaranteeing consistency between different operators or facilities). With a temperature resolution of 0.1°C and an overall accuracy of 0.5%, it meets the strictest industry benchmarks for flash point testing.

Adaptable to Petroleum Facility Environments: Petroleum labs and refineries often have variable conditions, but the VS-9806 performs reliably in temperatures ranging from 10°C to 40°C and relative humidity up to 85%RH—no specialized climate control needed. It also runs on a standard AC220V 50Hz±5% power supply with a power consumption of <300W, making it easy to integrate into existing laboratory setups without extra wiring or power upgrades.

Regulatory Compliance: The instrument’s heating rate strictly follows GB/T261-83 and GB/T261-2008 standards—two foundational protocols for petroleum flash point testing. This compliance ensures test results are recognized by regulatory bodies, customers, and industry partners, avoiding delays in product certification or market entry.

5. Delivers Long-Term Value for Petroleum Operations

Investing in the VS-9806 isn’t just a short-term fix—it’s a long-term asset for petroleum quality control:

Reduced Downtime: Its durable design and low maintenance needs minimize operational disruptions, keeping testing schedules on track.

Cost Savings: As a dual-function instrument (supporting both closed and open cup testing), it eliminates the need to purchase multiple flash point tester models, cutting equipment costs.

Scalability: Its automated workflow lets teams process more samples without adding staff, making it easy to scale as petroleum operations grow.

Risk Mitigation: By ensuring accurate, compliant test results, it protects facilities from regulatory fines, product recalls, and reputational damage—priceless for petroleum businesses operating in a highly regulated industry.

Final Verdict: The Must-Have Flash Point Tester for Petroleum Quality Control

For the petroleum industry, quality control isn’t optional—it’s mandatory. The VS-9806 Automatic Closed (Open) Flash Point Tester stands out as the ideal flash point apparatus for this critical work: it’s accurate, user-friendly, compliant with industry standards, and built to solve the unique challenges of petroleum flash point testing. Whether you’re a refinery testing diesel batches or an aviation fuel supplier verifying product safety, the VS-9806 isn’t just a tool—it’s a partner in delivering safe, high-quality petroleum products. For any petroleum business committed to excellence, this closed cup flash point tester is an essential investment that pays off in safety, efficiency, and long-term success.