- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

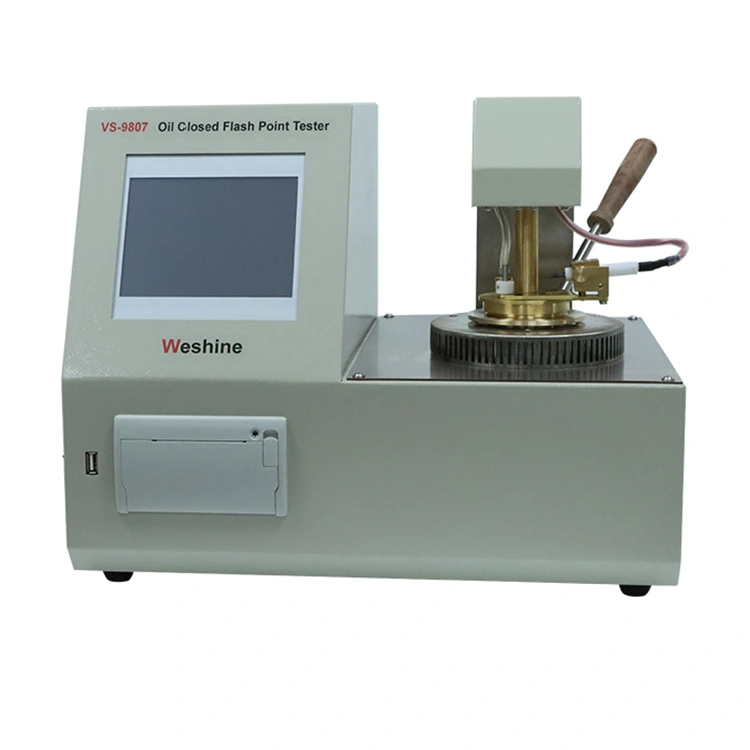

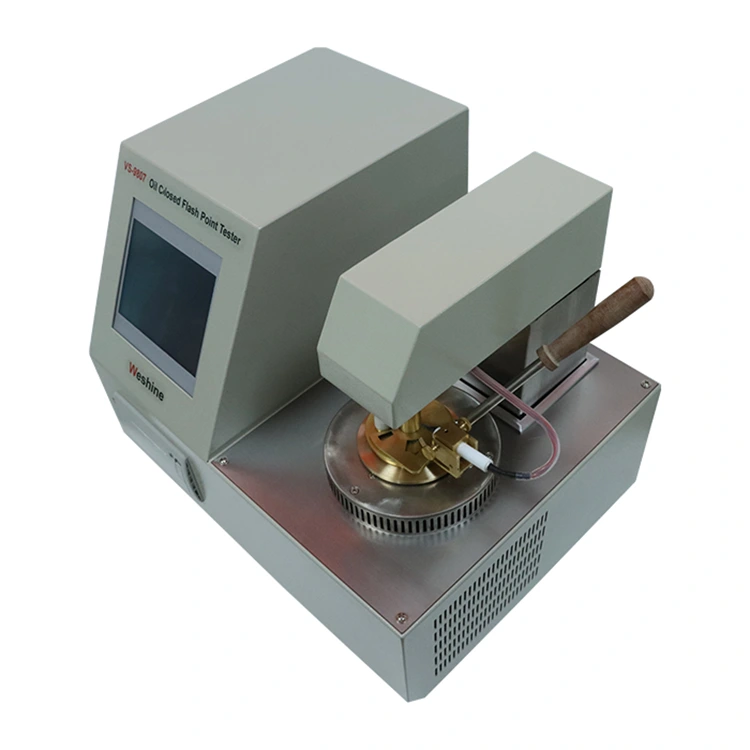

Flash Point Tester

In the dynamic domain of petroleum product testing, finding a flash point tester that balances advanced features, versatility, and industry compliance is essential for teams across sectors. The VS-9807 Fully Automatic Closed (Open) Flash Point Tester stands out as a game-changing solution—unlike single-function tools such as the cleveland open cup flash point tester (which only handles open cup testing), it integrates both closed and open cup capabilities while meeting strict standards like GB/T261-2008 and ISO2719. This blend of innovation and flexibility makes it a go-to flash point tester for industries ranging from oil and railway to aviation, electric power, and scientific research, addressing unique testing needs across diverse scenarios.

Send Inquiry

VS-9807 Flash Point Tester: Feature-Rich Solution with Diverse Application Scenarios

In the dynamic domain of petroleum product testing, finding a flash point tester that balances advanced features, versatility, and industry compliance is essential for teams across sectors. The VS-9807 Fully Automatic Closed (Open) Flash Point Tester stands out as a game-changing solution—unlike single-function tools such as the cleveland open cup flash point tester (which only handles open cup testing), it integrates both closed and open cup capabilities while meeting strict standards like GB/T261-2008 and ISO2719. This blend of innovation and flexibility makes it a go-to flash point tester for industries ranging from oil and railway to aviation, electric power, and scientific research, addressing unique testing needs across diverse scenarios.

Product Features: Precision and Innovation That Outperform Traditional Testers

Every feature of the VS-9807 is engineered to solve common pain points in petroleum testing—from inconsistent results to inefficient workflows—outshining both basic flash point tester models and specialized tools like the cleveland open cup flash point tester in versatility.

1. Advanced Digital Signal Processing: The Foundation of Reliable Testing

At the core of the VS-9807 lies a high-speed digital signal processor, a critical upgrade from conventional flash point tester setups (including older cleveland open cup flash point tester variants) that struggle with signal lag or interference. This processor ensures stable, uninterrupted operation even in demanding environments—whether running 24/7 tests in a refinery or handling precision experiments in a lab. By eliminating data inconsistencies, it lays the groundwork for accurate, repeatable flash point readings, a must for teams relying on test data to make safety or quality decisions.

2. Fully Automated Testing Cycle: Efficiency for High-Volume Needs

The VS-9807’s fully automated workflow is a standout advantage over manual or semi-automatic tools—including many cleveland open cup flash point tester models that require manual ignition, cooling, or report generation. Every step of the test is automated: from opening the test chamber lid (critical for closed cup mode) and initiating ignition to triggering safety alarms, cooling the system, and printing results. This not only slashes human error (a major risk when switching between closed and open cup tests) but also cuts testing time by up to 40%, making it ideal for high-volume scenarios like refineries testing daily diesel batches or aviation facilities verifying jet fuel quality.

3. Platinum Heating Wire Ignition: Consistency for Accurate Detection

Ignition variability is a top culprit behind unreliable flash point results—especially for high-flash-point products often tested with a cleveland open cup flash point tester. The VS-9807 uses a platinum heating wire ignition system, which outperforms the flame ignition used in many traditional flash point tester models. Platinum’s exceptional thermal stability ensures uniform, predictable ignition across every test—whether analyzing closed cup gasoline or open cup heavy lubricants. This eliminates inconsistencies in test initiation, guaranteeing that every reading meets GB/T261-2008 and ISO2719 standards.

4. Atmospheric Pressure Auto-Correction: Universal Accuracy Anywhere

Atmospheric pressure fluctuations can skew flash point results, a challenge that plagues standalone cleveland open cup flash point tester models (which often require manual adjustments). The VS-9807 solves this with automatic atmospheric pressure measurement and real-time correction. It continuously monitors pressure during testing and adjusts results to account for changes—whether you’re testing in a high-altitude refinery, a coastal storage facility, or a mobile lab. This universal accuracy ensures consistent quality control across multiple sites, eliminating the risk of non-compliant results due to environmental variables.

5. Adaptive PID Control Algorithm: Optimal Temperature for Every Test

Temperature control is make-or-break in flash point testing, and the VS-9807’s adaptive PID control algorithm sets a new standard. Unlike basic flash point tester models with fixed heating rates (which can overheat or underheat samples), this intelligent system adjusts heating speeds based on industry-standard temperature curves. For closed cup tests (e.g., gasoline), it ramps temperature gently to prevent premature vaporization; for open cup tests (e.g., lubricants, a common cleveland open cup flash point tester use case), it slows heating to align with open cup best practices. The result? Perfect thermal conditions for every test, balancing speed and accuracy while ensuring compliance.

6. Over-Temperature Protection: Safety First for Flammable Samples

Testing flammable petroleum products demands robust safety features—especially in open cup mode, where fire risks are higher than closed cup (a concern familiar to cleveland open cup flash point tester users). The VS-9807 integrates over-temperature protection: if temperatures exceed safe limits, it immediately stops testing and triggers a loud alarm. This safeguards both laboratory personnel and the instrument, preventing equipment damage and potential fires. Unlike older flash point tester models with reactive safety measures, this proactive system addresses risks before they escalate.

7. Thermal-Sensitive Micro-Printer: Flexible Documentation for Compliance

Comprehensive test documentation is non-negotiable for petroleum industry compliance, and the VS-9807’s thermal-sensitive micro-printer simplifies this process. Unlike some cleveland open cup flash point tester models that require a separate computer for reporting, this printer generates clear, professional reports directly from the instrument—even offline. Whether you need to print results immediately after a closed cup diesel test or store data for later documentation of open cup lubricant analysis, it ensures you have a physical record of every test. This flexibility is a lifesaver for audits or customer reporting, reducing manual logging errors.

8. Intuitive LCD TFT Touch Screen: Accessibility for Every Team

Advanced technology shouldn’t require expert training—and the VS-9807’s design ensures usability for all. It features an LCD TFT true-color touch screen paired with a fully Chinese man-machine interface, making navigation intuitive. Clear prompt menus guide users through parameter entry: whether setting pre-value temperatures for closed cup gasoline tests or adjusting ignition intervals for open cup lubricant analysis (mimicking cleveland open cup flash point tester precision), the system eliminates guesswork. This reduces training time for new staff and ensures consistent operation across rotating shifts—critical for busy facilities.

Application Scenarios: Where the VS-9807 Delivers Maximum Value

The VS-9807’s versatility makes it indispensable across industries, addressing unique flash point testing needs that often require multiple tools (like a basic flash point tester plus a cleveland open cup flash point tester) to solve.

1. Petroleum Industry Quality Control

Oil refineries and petrochemical plants rely on the VS-9807 to test the flash points of fuels (gasoline, diesel), lubricants, and specialty petroleum products. Its dual closed/open cup capability eliminates the need for separate testers, while automation handles high-volume batches efficiently. By ensuring products meet safety standards before market release, it prevents fire hazards and avoids regulatory penalties—critical for maintaining brand trust.

2. Railway and Aviation Fuel Testing

Railway companies and airlines demand absolute accuracy in fuel testing: even minor flash point deviations can lead to in-transit fires or equipment malfunctions. The VS-9807’s precision (repeatability ≤2°C) and compliance with GB/T261-2008 make it ideal for verifying diesel (railway) and jet fuel (aviation) quality. Its automation also speeds up testing, ensuring fuel supplies stay on schedule for trains and planes.

3. Electric Power Sector

Power plants use petroleum products (e.g., diesel for backup generators) to maintain uninterrupted power supply. The VS-9807 tests these fuels to ensure safe storage and use—its atmospheric pressure auto-correction is especially valuable for plants in high-altitude areas, where pressure fluctuations can affect flash point readings. By preventing accidental ignition, it safeguards critical power infrastructure.

4. Scientific Research and Academic Institutions

Universities and research labs use the VS-9807 to study new petroleum-based materials, analyze fuel composition, and develop advanced testing methods. Its precision (0.1°C resolution) and advanced features (adaptive PID control) make it a tool for innovation—whether researching eco-friendly fuels or optimizing lubricant performance. Unlike the cleveland open cup flash point tester, it handles both closed and open cup experiments, supporting diverse research goals.

5. Regulatory and Compliance Testing

Government agencies and certification bodies trust the VS-9807 for official testing, as it adheres to GB/T261-2008 and ISO2719. Its reliable results ensure petroleum products on the market meet national and international standards—whether inspecting imported fuels or verifying manufacturer claims. The thermal printer’s documentation capability also simplifies audit trails, making compliance seamless.

Final Verdict: The VS-9807 Versatile Flash Point Tester for Every Industry

The VS-9807 Fully Automatic Closed (Open) Flash Point Tester isn’t just a feature-rich tool—it’s a cost-effective, efficient alternative to owning multiple instruments (like a basic flash point tester and a cleveland open cup flash point tester). Its advanced features solve common testing pain points, while its diverse application scenarios make it indispensable for oil, railway, aviation, electric power, and research sectors. For teams prioritizing accuracy, compliance, and usability, the VS-9807 delivers unmatched value—ensuring safety, quality, and operational excellence in every flash point test.